Bulk powder truck is also called powder material truck, bulk cement truck. This article introduces the ash unloading process of the powder material truck. Because the chassis and modified parts of each manufacturer are different.

1.Tank pressure

The vehicle fires up and the remote throttle is applied. At this time, the idle speed of the engine is significantly higher and the clutch is stepped on.

At this time, the power take-off switch is turned on and the third gear is engaged, and the clutch is released. (For the fast variable box, you must step on the clutch and engage the gear, so that the power take-off can be combined)

Reminder: Be sure to check whether the tank cover and ash discharge valve are closed before pressing

Adjust the speed of the air compressor to 80-100 with the electronic throttle control handle, and look at the tank pressure gauge. The ash can be unloaded when the tank pressure reaches 0.2mpa. Open the secondary air ball valve (blowing aid valve) to clear the storage bin pipe.

Open the unloading butterfly valve to start unloading. (You can also open the auxiliary blow valve) When the pressure drops to about 0.04mpa and no longer drops, it means that the material has been unloaded, and the unloading operation is over.

If the vehicle is parked in an uneven position or the dryness of the material is not enough, it is necessary to sweep the warehouse.

2.The process of sweeping warehouse

After the unloading valve is opened, the material is unloaded normally, and under normal circumstances, the rear warehouse is finished first. Because the back chamber is closest to the ash discharge pipe, pay attention to the pressure of the pressure gauge. If the pressure goes down too fast, close the rear bin unloading butterfly valve at this time. (The back warehouse has been finished)

Keep the front bin open. When the pressure in the front bin drops rapidly, there is not much material left in the front bin. At this time, close the discharge valve of the front bin and wait for a few minutes. (Waiting for a few minutes is for the pressure to rise enough, and the air chamber shakes the canvas to gather the bulk materials in the tank together) When the air pressure reaches 0.2mpa, first open the auxiliary blow valve, and then open the discharge butterfly valve of the first warehouse.

When the pressure of the first warehouse drops too fast, the first warehouse has been cleaned at this time, and the first warehouse is closed. Butterfly valve for material, open the unloading valve of the rear warehouse, until the air pressure of the tank is finished, the whole vehicle material is completely finished, the cement powder of the two warehouses is about 25 square meters, and the normal unloading time is 23 minutes.

3.Clean up after unloading

After unloading, make sure that the air pressure in the tank is completely exhausted before opening the tank cover to avoid danger!

The tank mouth gasket and the tank mouth must be cleaned, otherwise the seal will not be tight, and the gasket will be damaged and leak air after a long time, so maintenance must be very important.

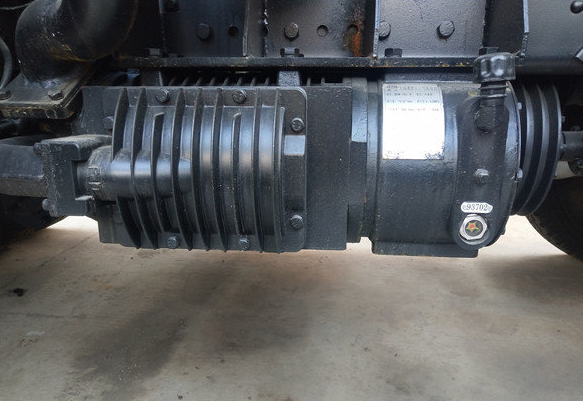

4.Air compressor maintenance

The air compressor is a key part of the bodywork, and maintenance is very important.

The oil in the air compressor should be replaced frequently, the air inlet should be cleaned frequently, the filter screen should be replaced, and the screws of the air compressor and drive shaft should be locked frequently.