The market is full of various cement bulkers, making many consumers have a choice barrier. Therefore, this article extracts the simplest and easy-to-understand method from the information on the Internet and the professional experience of the team to answer the questions you may have when purchasing a cement bulker truck, including capacity, volume, size, budget, length and The latest technical specifications.

If you already know the cement bulker truck well, or are too lazy to know so much, you can also directly view the 4 cement bulk trailers we recommend from the catalog, and there are as many as 10 other types of cement bulk trailers for reference.

There are many Types of Cement Tankers on the market, and many customers do not know how to choose when purchasing. This article tells you Types of Cement Tankers.

The tank truck series is divided into oil tank truck, concrete mixer truck, powder material and bulk cement truck, water supply truck and so on.

The tank body is manufactured through three-dimensional design and advanced processing technology.

The chassis adopts the special chassis of various manufacturers, with advanced technology and reliable performance. Delivery truck with canned containers.

5 advantages of dry bulk trucks:

High loading and unloading transportation efficiency.

Guarantee the quality of the goods.

Conducive to transportation safety.

Reduce labor intensity and improve loading and unloading conditions.

Save packaging materials and save labor. Reduce shipping costs.

Types of Cement Tankers

Tank car

Shipment of fuel oil, lubricating oil, acids, alkalis, water, food and beverages, etc. Powder tank cars: shipment of cement, flour, stone powder, etc.

Oil tank trucks are also called mobile fuel trucks, computer tax-controlled fuel trucks, oil tank trucks, oil loading trucks, oil trucks, oil trucks, oil trucks, and edible oil trucks. They are mainly used as petroleum derivatives (gasoline, diesel , crude oil, lubricating oil and coal tar and other oil products) transportation and storage.

According to different purposes and usage environments, it has various functions of refueling or transporting oil, and has the functions of oil absorption, oil pumping, packing and releasing of various oils, etc.

- Shipment of fuel oil,

- Lubricating oil

- Acids

- Alkalis

- Water

- Food and beverages, etc.

Tank material

Carbon steel, stainless steel, aluminum alloy, pure aluminum tank, rubber lining, rotational molding, plastic tank, glass fiber reinforced plastic tank can also be used as needed.

Tank type

Square round, oval, round

Oil pumps

Self-priming pumps, gear pumps, chemical pumps, stainless steel pumps, centrifugal pumps, heavy oil pumps. Fuel meter: single count, double count, tax-controlled fuel dispenser.

Oil tanker tank structure

The oil tank truck is composed of a special vehicle chassis and an upper part, and the upper part is composed of a tank body, a power take-off, a transmission shaft, a gear oil pump, a pipe network system and other components. The pipe network system consists of oil pump, three-way four-position ball valve, two-way ball valve, filter screen and pipeline.

Concrete mixer truck

A special truck used to transport concrete for construction; it is also often called a snail truck because of its shape. These trucks are equipped with cylindrical mixing drums to carry the mixed concrete. During transportation, the mixing drum will always be kept rotating to ensure that the carried concrete will not solidify. After the concrete is transported, the inside of the mixing drum is usually washed with water to prevent the hardened concrete from taking up space, making the volume of the mixing drum less and less.

Concrete mixer truck parts

Concrete mixer truck is composed of automobile chassis, mixing drum, transmission system, water supply device and other parts. Due to technical bottlenecks, the four major components of domestic mixer trucks are all imported components.

Mixer composition

Second-class chassis, transmission system, hydraulic system, frame, mixing tank, feeding and discharging device, water supply system, control system, people’s ladder and other parts. The front end of the mixing tank is connected with the reducer and installed on the front of the frame, and the rear end is supported by two rollers installed on the back of the frame through the raceway.

Powder material dry bulk trailer

Powder material transport vehicle is also called bulk cement vehicle, dry bulk trailers, pneumatic tankers which is composed of special vehicle chassis, bulk cement vehicle tank body, gas pipeline system, automatic unloading device, manufactured with a single compartment made of aluminum or steel, with a capacity of 30-100 cubic meters.and other parts.

It is mainly used in cement plants, cement warehouses and large construction sites, which can save a lot of packaging materials and loading and unloading labor.

Pneumatic tankers are used in a variety of industries including construction, food and industrial manufacturing and transporting cargo such as:

Construction materials such as sand and cement

Dry foods such as sugar, flour and starch

chemical powder

powder material particle

Before you start purchasing cement tank trucks, please clarify these questions first:

- What is the cement tank truck product?

- How much is a cement tank truck worth?

- What is the special performance of the cement tank truck?

- If the product is plastic pellets, what color?

- How much weight does the cement tanker truck have to move?

- Are there scales at the loading location?

- What will you load the product from? Silo? subway? and many more. What kind of container would you unload it into?

- How close can you get the cement tanker to load and unload the product?

- How many hoses do cement tank trucks need to load and unload?

- What accessories and adapters are needed for loading and unloading?

- Does the cement tanker facility or the recipient’s facility require any specific safety equipment?

It is mainly used in cement plants, cement warehouses and large construction sites, which can save a lot of packaging materials and loading and unloading labor.

Construction materials such as sand and cement

Dry foods such as sugar, flour and starch

chemical powder

Water truck

Water supply trucks are also called water trucks, water trucks, water tank trucks, and tank trucks. It has the functions of transportation and water supply, and can hold hot water and drinking water to meet the needs of different users in different environments.

Drinking water tanks require non-toxic anti-corrosion treatment of carbon steel tanks, or directly use food-grade stainless steel tanks, but the price is expensive.

Classification of water supply trucks and water trucks

Water trucks are generally used for engineering water transportation and drought-resistant water transportation. The classification of water transportation vehicles is classified according to the functions of sprinklers. According to functions, they can be divided into greening, cleaning, engineering water transportation, drought-resistant water transportation, road sprinkling, and fire sprinklers. , The fire sprinkler can also be used for fire emergency.

The composition of the water supply truck

The water supply vehicle is composed of the vehicle chassis, the water inlet and outlet system and the tank body. Interpretation and standards Water trucks (yunshuiche) have a variety of spraying and water transportation functions according to different use environments and purposes,

According to different use environments and purposes, there are multiple spraying and water transportation functions. The multi-functional sprinkler integrates multiple functions and can generally be specially modified according to user requirements.

It is equipped with a special high-power sprinkler pump with leading quality in the country, with a fire-fighting connector, a self-flow valve, and a self-priming function. It can be equipped with an electric pump, a hot water pump, and a stainless steel pump.

Frequently Asked Questions When Purchasing Cement Bulk Trailer

What Should Different People Pay Attention to When Buying Cement Bulk Trailer?

According to the survey on the Internet and the questions you usually ask, capacity of cement bulker, cement bulker truck price, cement bulker specifications, cement bulker dimensions, cement bulker weight, cement bulker design, cement bulker unloading, is what netizens care most about when purchasing cement bulker truck top 7 considerations. As for how to judge whether the specifications of the cement bulker truck are good, we will discuss in detail in the next section “Cement Bulker Truck Selection Secret”.

In addition, different users pay different attention to different things, and the required cement bulker specifications are not the same.

Can You Buy a Useful Cement Bulk Trailer with a Low Budget?

There are already many cheap cement bulker trucks with good performance on the market. For example, panda can buy a cost-effective cement bulk trailer with a service life of more than 10 years for only US$13,500.

On the other hand, there are many cement bulker for sale models on the market. If you have a relatively sufficient budget, you can buy relatively large capacity 30t 40t cement bulk trailers that sell well in the market.

Therefore, it is really not necessary to spend a lot of money to buy a cement bulk trailer with stable performance and large loading capacity, unless you insist on the brand.

Is the Cement Bulk Trailer More Prone to Damage?

Cement bulker truck is the most important equipment in the bulk cement delivery system, and it is also the most vulnerable and vulnerable part with the highest failure rate. The bulk machine generally has a bulk head cone. Bulk machine cone and inner telescopic hose, bulk head lifting system, etc.

The damage to the rear of the cement bulker truck is caused by bumping into other objects when reversing, or being rear-ended by other vehicles. When the rear of the bulk cement truck is damaged, the rear bumper, rear body panels, luggage compartment and floor will be deformed.

The rear side quarters above the wheels may also bulge out. If the collision is severe, the rear side panel will fold up and hit the roof, the body pillar of the four-door vehicle will bend, and the rear side member will deform.

So when we drive a cement bulker truck, we must pay attention to safe driving, not only responsible for our own safety, but also responsible for the safety of others.

Tips for Choosing A Cement Bulk Trailer

How to Choose the Right Bulk Cement Trailer Manufacturers?

- First of all, reliable cement bulker truck manufacturers understand their own positioning. If you plan to buy cement bulker truck, then you need to understand whether you are looking for direct sales from the manufacturer or a dealer. Whether to go to the field to find or buy nearby.

- Secondly, let’s not be afraid of trouble, and go to a few more on-site inspections. Cement bulker truck manufacturers of large companies can conduct on-site research and investigation on testing equipment, equipment equipment, debugging equipment, after-sales personnel, business personnel, office areas, etc. Be sure to clarify what you don’t understand. For after-sales, transportation, training and other content, we must understand clearly one by one.

- Don’t try to buy good things at a low price at any time. It’s unrealistic. Cement bulker truck manufacturers must make a profit when they open their doors to do business. When you are not sure about the price, you can consult and investigate first, and you probably know the cement bulker truck price. You have to fully consider the reasons for some low-priced equipment, refurbishment, used cement tankers for sale are all possible, and in any case, the user will suffer a lot if encountered. So, don’t try to get the same or even better cement bulker truck for below market price.

Extended reading : How to Choose a Bulk Cement Tanker Manufacturer

Advantages of Cement Bulker Truck

Feature 1: Chassis Specialization

The high-quality high-horsepower chassis of the main engine factory is selected, which is specially developed for powder tank trucks. It is equipped with remote throttle and high-torque power take-off, and the performance is stable and reliable.

Feature 2: Lightweight

The bulk cement transport vehicle is made of high-quality low-alloy high-strength steel plates. The body has undergone many optimized designs, and the configuration is as light as possible. The whole vehicle is reduced by 800-1000KG.

Lightweight design mainly includes:

The tank body is made of high-quality high-strength steel, and the weight is further reduced through optimized design, achieving the ideal state of higher strength, lighter weight and reliable performance;

The upper platform, wheel cover, side protection and many other accessories can be made of aluminum alloy, which is lighter, more beautiful and more durable;

Feature 3: High Cost Performance

The material of the whole vehicle is upgraded, the weight is reduced, and the cost is reduced on the basis of ensuring performance;

Dozens of structural optimizations, on the premise of ensuring strength and performance, optimize or simplify the structure, save materials and reduce labor costs;

Adopt advanced equipment such as plasma and automatic welding to improve production efficiency and reduce overall cost;

The whole vehicle has reliable structure, excellent performance and affordable price;

Disadvantages of Bulk Cement Trucks

The cost of the whole vehicle is relatively high, and it is suitable for large-volume cement transportation.

For small-volume cement transportation, cement bulker bags trucks are more economical.

Flexible designs and a range of solutions help maintain our position as a supplier of customized, environmentally friendly and energy-efficient cement handling systems.

The Key Points of Choosing Cement Bulker Truck?

Capacity of Cement Bulker

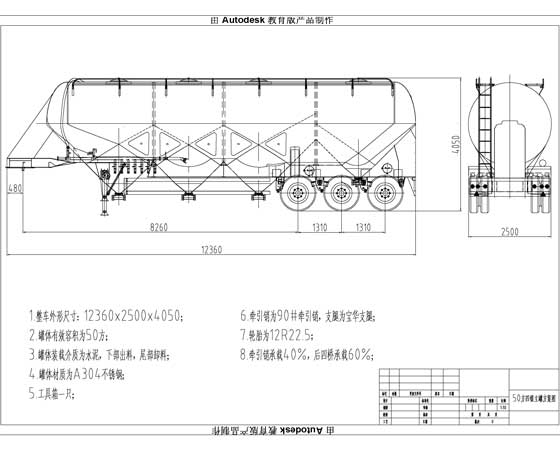

The main volume of the bulk cement tanker trailer is 35 cubic meters, 40 cubic meters, 45 cubic meters, 50 cubic meters, 60 cubic meters, 80 cubic meters, 100 cubic meters, but if you have a larger volume requirement, our factory can also custom made.

Cement Bulker Truck Price

At present, the cement bulker truck price on the market are inconsistent, and the approximate price ranges from 13,000-30,000 US dollars, because the selected capacity of cement bulker, dimensions, and specifications are different. In addition, there are some used cement bulker for sale on the market, and the cement bulker truck price is relatively cheaper.

If you want to know more about cement bulker truck, you can consult us and get the latest cement bulker truck price for free.

Cement Bulker Specifications

Bulk cement tank trucks are also called bulk cement trucks, powder tank trucks, tank trucks, and powder material transport vehicles. They are composed of special vehicle chassis, bulk cement truck tanks, gas pipeline systems, and automatic unloading devices.

Cement Bulker Dimensions

The most common size of a cement tanker is 13m2.5m, and the total size is about 17.5m including the front. The size of the powder tank truck is a semi-trailer, generally 2.5 meters wide, and there are also special 2.55 meters, 2.8 meters, and 3 meters; The standard length is 13 meters, and there are also 10 meters, 11 meters, 14.6 meters, 16 meters, and 17.5 meters. Size: (9500-12000)2500*(3300-4000)mm.

Different brands of cement tankers have different specifications and sizes.

Cement Bulker Weight

Since most of the bulk cement tankers on the market advertised that the weight is smaller than the actual weight, users who buy bulk cement trucks are now troubled by the above problems. So customers must pay attention to the cement bulker weight when purchasing.

Cement Bulker Design

When each customer purchases cement bulker, due to personal preferences and different usage conditions, the configuration, capacity, and volume will be different. Panda cement bulker manufacturerky can customize the cement bulker design for you according to the cement bulker drawing you provide. , design cement bulker according to your need.

Precautions for Unloading Bulk Cement Trucks

The unloading steps of the bulk cement transport vehicle are as follows: when the female end of the tanker is docked with the sub-end, the air compressor starts to blow compressed air into the tank, and the regulations require that the pressure gauge shows 0.2Kpa to start ash discharge.

This will take a long time, and the needle of the pressure gauge will always shake around a fixed value during normal dusting. At this time, the work is normal. When there is not much cement in the bulk cement tank, the relative space in the tank has increased, and the pointer reading begins to drop. When the pointer suddenly drops to the lowest point of Z (close to the “0” value of the pressure gauge), at this time, the air hole of the bulk cement flow tank will eject a large group of air-ash mixed airflow rapidly, which means that the flow tank The ash loading process is over.

After unloading, if the driver of the bulk cement tanker wants to check the remaining material in the tank of the bulk cement tanker, the first choice is to turn on the gas discharge switch to exhaust the remaining air in the tank, so as to avoid the incident of breaking the tank cover and hurting people when opening the tank cover. You can check the air pressure in the tank through the barometer, 0 means no air pressure in the tank.

The process of accepting bulk cement and precautions: users must master the process of bulk cement ash unloading, otherwise whether all the ash in the bulk cement tanker is unloaded will affect the benefits of the enterprise. Therefore, it is necessary to master the process of ash unloading. Pressure gauge changes and various features.

After the bulk car turns off the compressor and removes the connector, it can leave. The above indications show that all the cement in the bulk cement tanker is put into the tank, and the ash inlet can also be opened to check the degree of ash discharge of the cement tank.

The unloading process of a bulk cement truck seems simple, but it requires the driver’s careful and safe operation to ensure the smooth progress of the unloading process.

Cement Bulker Truck Safety Guide:

- Do not overspeed or overpressure when driving a bulk cement truck. Overspeed and overpressure will seriously damage the air compressor. The maximum speed of the machine is shown in the main technical parameter table, and the working pressure is 0.2MPa.

- Do not start or stop the air compressor quickly, but increase or decelerate slowly, otherwise, the punching force will damage the air compressor.

- Do not change the rotation direction of the air compressor, otherwise, the machine will be seriously damaged if the oil pump does not supply oil. the

- Do not stop the air compressor before decompression, otherwise, the powder material may flow back into the cylinder, causing serious damage to the air compressor.

- Check the oil level before starting the machine. The oil level should not be lower than the lower limit of the oil standard; it is necessary to check frequently whether the oil pump is supplying oil, if not, stop the machine immediately for inspection, otherwise, the lack of oil will seriously damage the air compressor.

- The lubricating oil should be replaced on schedule. After the new machine has been used for 30 hours, drain the oil in the crankcase, clean the inside of the crankcase and the oil filter, and then change the oil. After that, change the oil once a year as above. 7. Check and clean the oil filter. Under normal circumstances, check and clean once a quarter. If the machine has a high usage rate, check and clean once a month.

- The lubricating oil used in this machine is CD40 diesel engine oil. It is forbidden to mix lubricating oils of different brands, otherwise the deterioration of lubricating oil will affect the lubricating effect. the

- Maintain and clean the air filter every 30 hours of work. While rotating the filter element, blow it from the inside to the outside with compressed air with a pressure less than 0.6MPa. After five times of maintenance, please replace the new filter element. It is strictly forbidden to wash the filter element with oil or water.

High Quality Cement Bulker Truck Recommended

3 Axles 45 Cubic 55 Ton Cement Bulker For Sale

Brand: panda mech

Cement Tanker Price Range: $13,900-31,500

Delivery date: 7-25 days

Faster unloading: >1.5ton/min

3 Axle 30m3 40m3 50m3 Cement Tanker

Brand: panda mech

Cement Tanker Price Range: $21,900-32,500

Delivery date: 7-25 days

Faster unloading: >1.5ton/min

Application: transport Cement, PVC particles, fly ash, granular materials, etc.

V Shape Bulk Cement Trailer

1. Loading rate >98% fully filling

2. Residual rate <0.3%

3. Delivery height >15m suitable most silo

4. Faster unloading >1.5ton/min save fuel

Pneumatic trailers for sale

W-type powder tankers have two compartments, and the discharge angle of W-type bulk cement is generally larger than that of V-type bulk cement tankers, making discharge faster and more convenient

Recommended Article

- The Advantages and Disadvantages of 3 Types of Dry Powder Granular Material Truck

- 2023 Top 10 Best China Cement Tanker Manufacturers

- 2 Taboos: Maintenance of Bulk Powder Tankers

- Choose the Right Ecuador Cement Bulker Tank Truck

- What is the Best End Dump Trailer on the Market

- 12 Best Dump Trailer Manufacturers in the World (2023) – PANDA

Cement Bulker Truck FAQ

What do people pay attention to when buying cement bulker

According to the survey, capacity of cement bulker, cement bulker truck price, cement bulker specifications, cement bulker dimensions, cement bulker weight, cement bulker design, and cement bulker unloading are the top seven considerations that netizens care most about when purchasing cement bulker.

How to choose cement bulk trailer?

- Check cement bulk trailer configuration (air compressor, motor, suspension system, air system)

- Whether it is a manufacturer (can be visited on the spot, the production process is standardized, and the delivery date)

- After-sales service (perfect after-sales service, supported by technical personnel)

Do you have to buy the used cement tank truck?

It depends on the financial situation in your hand. It is recommended to purchase a new cement tank truck if the financial situation permits. After all, you get what you pay for in quality. Most of the used cement tank trucks have some performance problems or relatively long service life. For a long time, the maintenance cost in the later period is not low.

The above is the classification of cement bulker trucks. If you don’t know or are not sure about the volume, capacity or other questions of the cement bulker trucks you are using, our panda dry bulk trailer manufacturers can guide you through the whole process. dry bulk trailer manufacturers, one of the professional semi-trailer manufacturers in China, is committed to providing personalized one-on-one service to ensure that no effort is spared to find the right dry bulk trailer for you. Contact panda cement bulker truck manufacturers now to ensure our tanks A trailer can meet all your goals!

We offer drained cement bulker truck trailers, tipper trailers, flatbed trailers, tank trailers and more! Anything you can think of in the cement bulker truck trailer world, we’ll find it for you!