When cement porters move cement, it is easy to cause dust to fly all over the sky. Working in such an environment is definitely not good for the health of cement workers. How to solve problems? This article takes you to answer cement transport vehicle question.

How is bulk cement transported?

Bulk cement comes in two packaging types: bagged and bulk.

1.Traditional bagged cement transportation process

Why is there so much dust, please see this picture:

You see, it is a layer of woven bags, which is also for cost considerations, because the cement industry is currently an industry with excess capacity, and the price of cement is low. Only by reducing costs can companies maintain meager profits. The cost difference of each woven bag is 10 cents. It will cost an extra 0.1 yuan X 20 bags X 10,000,000 tons = 20 million yuan a year.

2.Bulk cement transport vehicle

It is transported to the two high grinding bins through a closed cement transport vehicle, then mixed with water, stones, and sand, and put into the mixer truck parked below. This truck handles the flowing concrete (cement, water, and sand) After the stones are mixed, it is called concrete) and transported to the construction site, this process is dust-free.

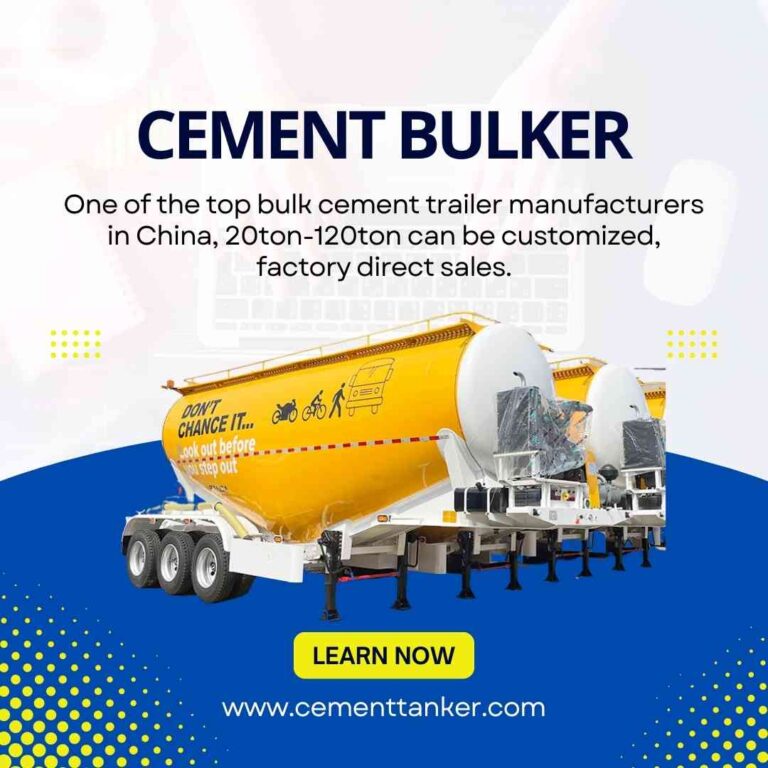

What is Bulk Cement Transport Truck?

The bulk cement transport truck also known as bulk cement tankers, cement transport vehicle,cement powder tanker is specially designed for transporting large quantities of dry dust materials, such as fly ash, cement, lime powder, mineral powder, etc., with a particle size of no more than 0.1 mm.

Bulk Cement Transport Truck working principle

Bulk cement transport vehicle,The cement dust is flowed by compressed air, and then the loading, unloading and transportation with almost zero pollution are realized.

Bulk cement transport vehicle advantage

Bulk cement transport vehicle is mainly used in cement plants, cement warehouses and large construction sites, which can save a lot of packaging materials and loading and unloading labor.