Screw Air Compressor vs Swing Rod Air Compressor vs Piston Air Compressor

The air compressor is one of the essential parts of the bulk cement transporter. Most of the bulk cement transporters in China use the swing rod type air compressor, but most of the foreign countries use the screw type air compressor. What is the difference between the two, the bulk cement transporter manufacturer will take you to learn more.

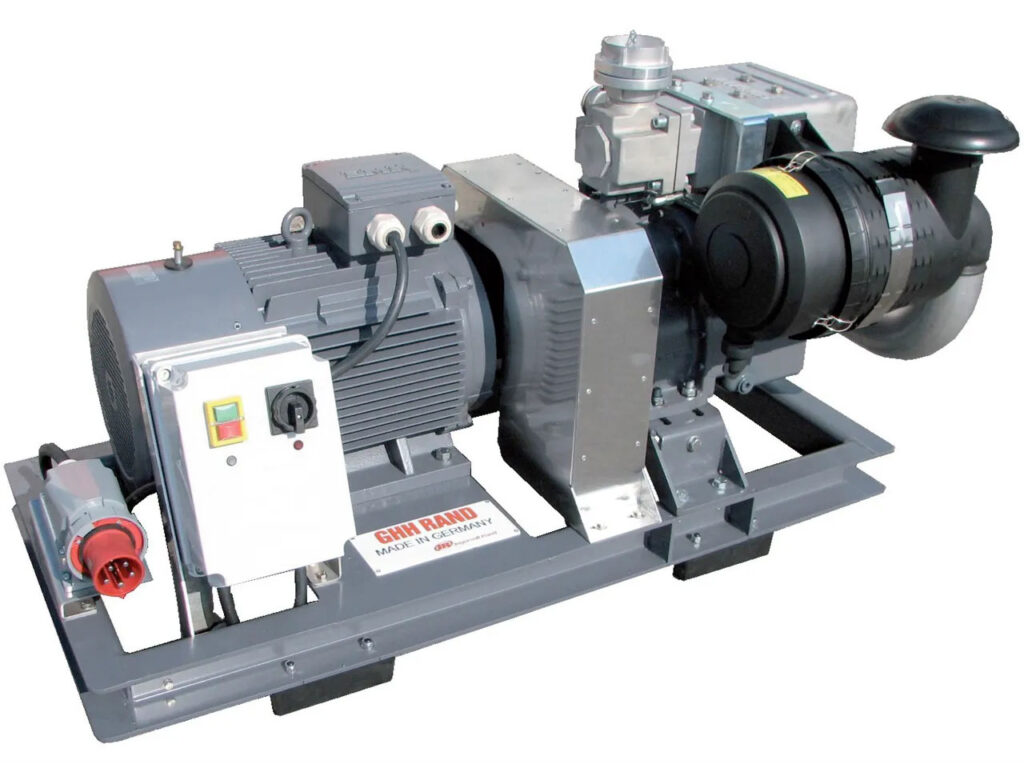

The panda bulk cement transporter manufacturer uses the German GHH screw air compressor, which has a long service life and low vibration. It does not need to be fixed on the foundation with anchor bolts. The motor power is low, the noise is low, the efficiency is high, the exhaust pressure is stable, and there is no easy Damage parts, etc

What is an oil-free screw compressor

Oil-free screw compressors can provide pollution-free compressed air for the pneumatic conveying of various dry bulk trucks.

From high density powders to low particle sizes, GHH RAND compressors efficiently and reliably handle a range of dry bulk products.

GHH screw compressor application

- Powder - Cement, Lime

- Granules - Sand, Salt

- Cobblestone - Grit

Oil-free Lubricated Swing Rod Compressor

The oil-free swing rod compressor is a new type of compressor developed in the late 1960s and early 1970s. It has the advantages of simple structure, small size, light weight, few parts, small vibration, and easy operation. It is reliable and easy to install. It is suitable for places where the discharge pressure is lower than 0.7MPa and the gas volume is lower than 30m~3/min without oil gas.

At present, the machine has been widely used in bulk cement trucks as a power source for air blowing cement, but it is not widely used in other occasions.

The working principle of the swing rod compressor

The pendulum type compressor is a miniature reciprocating piston type compressor. The motor is driven by a single shaft and has a symmetrical distribution of crank-rocker mechanical structure. The main motion pair is a piston ring, and the auxiliary motion pair is an aluminum alloy cylindrical surface. Self-lubricating without adding any lubricant.

The volume of the cylindrical cylinder changes periodically through the reciprocating motion of the crank and rocker, and the volume of the cylinder changes twice in opposite directions for one cycle of the motor.

When the positive direction is the expansion direction of the cylinder volume, the cylinder volume is vacuum, the atmospheric pressure is greater than the air pressure in the cylinder, and the air enters the cylinder through the intake valve. At this time, it is the suction process: when the reverse direction is the volume reduction direction, the gas entering the cylinder is subjected to Compression, the pressure in the volume increases rapidly, when it is greater than the atmospheric pressure, the exhaust valve is opened, and the exhaust process is at this time.

The structure arrangement of single-shaft double-cylinder makes the gas flow rate of the compressor twice that of the single-cylinder when the rated speed is fixed, and the vibration and noise generated by the single-cylinder compressor can be well solved, and the overall structure is more compact.

Screw Air Compressor vs Swing Rod Air Compressor:

In terms of price:

The price of the screw air compressor is 7-8 times that of the pendulum air compressor, and the price is too expensive.

performance:

The foreign screw air compressor rod has mature technology, high efficiency, fast pressure rise, fast discharge, high air cleanliness, light weight, fast discharge, and can load more bulk cement;

In the same time, you can run several times to improve work efficiency;

The screw air compressor has a long service life, and the service life is 5-10 times that of the pendulum type.

In China, the bulk cement transporter is seriously overloaded, the air compressor loss is relatively serious, and the swing rod air compressor has a high failure rate, which greatly shortens the service life.

In terms of comprehensive loading and unloading efficiency, the use of foreign vehicle-mounted screw machines is higher than that of domestic pendulum rods, the initial investment is high, and the investment recovery is also fast.

Piston air compressor VS screw air compressor

Different structure

Piston Type Oil Free Lubricated Air Compressor

The piston type oil-free lubricated air compressor is composed of compressor host, cooling system, regulating system, lubrication system, safety valve, motor and control equipment. The compressor and motor are fastened on the base with bolts, and the base is fixed on the foundation with anchor bolts.

Screw Air Compressor

The screw air compressor is composed of screw head, motor, oil and gas separation barrel, oil pipeline system, cooling system, air conditioning system, lubrication system, air pipeline system, safety valve and electrical control system. The whole machine is installed in a box, which is self-contained and can be placed directly on the flat cement floor without using anchor bolts to fix it on the foundation. is gradually being accepted by the market. In the next 10 years, screw compressors will gradually replace piston compressors.

The screw head is a dual-shaft positive displacement rotary compressor head. A pair of high-precision main (male) and auxiliary (female) rotors are installed inside the casing horizontally and in parallel, the main (male) rotor has 5 teeth, and the auxiliary (female) rotor has 6 teeth. The diameter of the main rotor is large, and the diameter of the auxiliary rotor is small. The teeth form a spiral, and the two mesh with each other. Both ends of the main and auxiliary rotors are supported and positioned by bearings respectively.

work differently

Piston Type Oil Free Lubricated Air Compressor

When working, the motor directly drives the crankshaft through the coupling, drives the connecting rod, the crosshead and the piston rod, so that the piston reciprocates in the cylinder of the compressor to complete the process of suction, compression and discharge. The machine is a double-acting compressor, that is, the piston moves up and down with air suction, compression and discharge.

Screw Air Compressor

When working, the motor directly drives the main rotor through the coupling (or belt), because the two rotors mesh with each other, the main rotor directly drives the auxiliary rotor to rotate together. The cooling liquid is directly sprayed into the rotor meshing part by the nozzle at the lower part of the compressor casing, and mixed with the air to take away the heat generated by the compression to achieve the cooling effect. At the same time, a liquid film is formed to prevent direct metal-to-metal contact between the rotors and close the gap between the rotors and the casing. The injected coolant also reduces noise from high-speed compression.

The main components of the screw air compressor are the screw head and the oil and gas separation barrel. The screw head is sucked in through the suction filter and the intake control valve, and the oil is injected into the air compression chamber to cool and seal the head and lubricate the screw and bearing, and the compression chamber generates compressed air.

The oil-gas mixture generated after compression is discharged into the oil-gas separation barrel. Due to the action of mechanical centrifugal force and gravity, most of the oil is separated from the oil-gas mixture. The air passes through the oil and gas separation cylinder core made of borosilicate glass fiber, and almost all the oil mist is separated. The oil separated from the oil-air separation cylinder core is returned to the screw head through the oil return pipe.

An oil filter is installed on the oil return pipe. After the return oil is filtered by the oil filter, the clean oil flows back into the screw head. When the oil is separated, the compressed air leaves the oil cylinder through the minimum pressure control valve and enters the aftercooler. The after-cooler cools the compressed air and then discharges it to the air storage tank for use by each air unit. The condensed water is concentrated in the air storage tank and drained through the automatic drain or manually.

different characteristics

Piston Type Oil Free Lubricated Air Compressor

Under normal conditions, the compressed gas of the piston compressor does not contain oil, and no oil removal device is required. The disadvantages of this machine are that the motor power is too large, the exhaust pressure is not stable enough, the exhaust temperature is high, the noise is too large, the maintenance workload is large, and the maintenance cost is high.

The piston ring in the cylinder of the oil-free air compressor and the packing in the packing device are filled with PTFE with self-lubricating properties as the sealing element. Therefore, the cylinder and packing device do not need to be lubricated with lubricating oil. Under normal circumstances, the compressed gas is basically pure and free of oil pollution, and there is no need to add a degreasing device. The disadvantages of this machine are that the motor power is too large, the exhaust pressure is not stable enough, the exhaust temperature is high, the noise is too large, the maintenance workload is large, and the maintenance cost is high.

Screw Air Compressor

The screw air compressor has the advantages of small vibration, no need to use anchor bolts to fix the foundation, low motor power, low noise, high efficiency, stable exhaust, and no wearing parts.

The precise coordination between the female and male rotors of the screw air compressor and the rotor and the body casing reduces the leakage of gas backflow and improves the efficiency; only the mutual meshing of the rotors, without the reciprocating motion of the cylinder, reduces vibration and noise sources.

4 advantages of screw air compressor

High performance and high efficiency

Air compressor equipment-screw air compressor adopts high-capacity compression components, and its rotor outer circle speed is low and achieves optimal oil injection, achieving high efficiency and high reliability. Guarantees optimum cooling and maximum service life for all components.

Driving concept

Screw air compressors drive the compression components at the optimum speed for the application through an efficient drive system. Completely maintenance-free during normal operation. It has the advantages of maintenance-free, high reliability and high efficiency.

Low maintenance cost

The original compressor design of the screw air compressor saves unnecessary maintenance costs. All components are designed for long life, and the large size inlet filter, oil filter and fine separator ensure optimum compressed air quality. All oil filters and separator components up to 22kW (30hp) are centrifugally opened and closed, further reducing maintenance time. “Speed up to repair point” enables repair work to be completed within minutes, greatly reducing downtime and repair costs.

Built-in intelligent control

To reduce operating costs, precise operational control is essential. All screw compressors are equipped with an intelligent control system with an easy-to-use control menu.

The single-screw air compressor is also called the worm air compressor. The meshing pair of the single-screw air compressor consists of a 6-head screw and two 11-tooth star wheels. The worm is meshed with the two star wheels at the same time. Even if the worm is in a balanced force, the displacement doubles. The volume of the air compressor is small, only 9 cubic meters per minute (9m3/min). The weight of the worm air compressor is only the piston type. 1/6 of .

6 advantages of swing rod air compressors

1) Throttling control can be used;

2) The structure of the pendulum type air compressor is not complicated, and the performance of continuous use is quite good. At the same time, compared with the reciprocating air compressor, a lot of consumable parts are greatly reduced, and it has the advantage of easy maintenance;

3) The airtightness of the shaft seal of the swing rod air compressor is good, while the airtightness of the shaft seal of the centrifugal compressor used for high speed cannot reach 100%, so it is not suitable for the compression of any gas other than air or nitrogen;

4) Within a certain air volume range, the diameter and shape of the rotor can remain unchanged, but only the pendulum rotor needs to be lengthened or shortened to meet the needs of different air volumes. This feature can reduce manufacturing costs and help market competitiveness;

5) The noise level of the swing-rod air compressor can be said to be the highest among all air compressors. The noise level depends on the air volume and often exceeds 100dbA. Therefore, the swing-rod air compressor must be equipped with a soundproof cover. thus giving a better impression;

6) Like the reciprocating air compressor, it has the same characteristics as the fixed displacement air compressor, and the exhaust pressure has a wide variation range.

different faults

Piston Type Oil Free Lubricated Air Compressor

The piston ring and packing device of this machine do not need oil lubrication. Under normal circumstances, the compressed gas is basically pure and free of oil stains. However, because the oil scraping ring often does not scrape oil completely and the sealing is not good, oil often runs to the packing device and even the piston ring, so that the compressed gas contains oil. In addition, the exhaust temperature is high, sometimes as high as 200 ° C; the cooler is blocked, so that the cooling effect is not good; the piston ring is stained with oil, which is particularly easy to wear; the valve flap leaks; the cylinder liner is worn, etc.

Screw Air Compressor

There are few failures of screw air compressors, and only need to do regular maintenance, replace the air filter, oil filter and oil and gas separator, etc., to ensure its normal operation. The maintenance of the two 10m3 screw machines used outside the maintenance is the blockage of the sewage pipe and the failure of the control panel. For the past two years, the main engine system has been running normally.

Disadvantages of pendulum air compressors:

The compressed air of the oil-operated swing-rod air compressor contains oil, which is not suitable for the food industry;

The oil-free swing rod compressor body only has a life span of 3-5 years, and the technology of replacing the air compressor body is often reserved by the original manufacturer. Therefore, the cost of replacing the entire set of air compressor bodies will generally exceed the cost of purchasing a new one. 60%, which is also a big criticism of users of this type of air compressor;

The swing rod type air compressor has high requirements on the quality of lubricating oil, and needs to be regularly maintained such as lubricating oil replacement and filter element replacement, and the maintenance cost is high;

Due to the precipitation of impurities in the lubricating oil and the formation of oil scale, the rotor in the air compressor may be stuck after a long-term shutdown of the swing rod air compressor after long-term operation;

The gap that must exist between the swing rods results in unsatisfactory air tightness, which is the main reason for the poor energy efficiency of oil-free swing rod air compressors, and it can even be said to be the worst among all types of air compressors with the same volume. ; The oil-injected swing-rod air compressor solves this problem, but the pressure loss caused by the oil filter element increases the consumption of a certain proportion of energy.

Summary

From the use effect, the screw air compressor has the incomparable advantages of the piston air compressor, which not only reduces the labor intensity of the operator, but also does not need to be equipped with maintenance workers, which greatly reduces the maintenance cost. On the other hand, when the piston machine is used, the exhaust pressure is occasionally too low, which causes the ion membrane control system to alarm. After switching to the screw machine, the exhaust pressure is set to 0.58MPa, the pressure remains stable, and no exhaust has occurred yet. The phenomenon that the pressure is too low causes the ion membrane control system to alarm, thus ensuring the safe production of the ion membrane system.

who are we ?

We are dry bulk tanker companies from China. The company mainly produces and sells pneumatic dry bulk trailer for sale, cement trailer for sale, and other types of semi-trailer. The company is headquartered in Jinan, Shandong, China. Our products are exported to 100+ countries around the world, serving 10,000+ Customers. Due to the products’ high quality and stable performance, we are favored by the world’s top 500 companies and have reached in-depth cooperation.

All the cement trailer parts produced by PANDA cement bulk trailer manufacturers adopt the most advanced brands in the industry, which can guarantee their quality and ensure stable product performance.