With the rapid development of urban construction, the demand for powder material transport vehicles is also increasing. The demand for powder material transport vehicles with a large volume in the market is getting higher and higher. Although large volume powder material transport vehicles Transport vehicles have many different forms of expression in structure, but their unloading principle is the same.

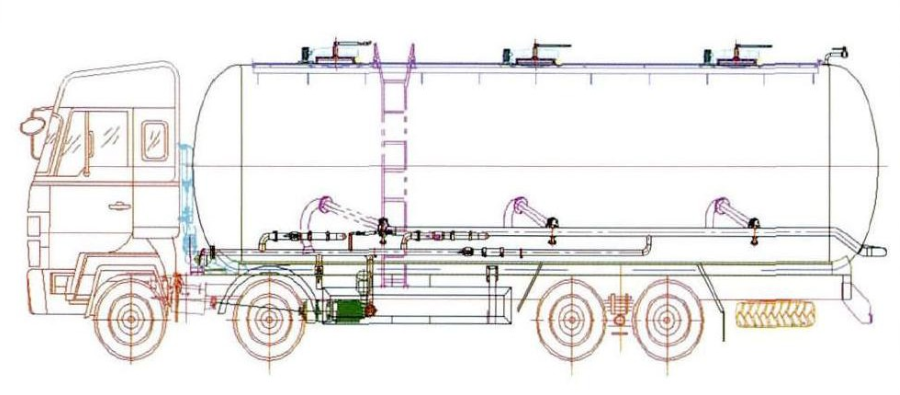

The unloading principle of bulk cement tanker:

The unloading principle of the bulk cement tanker is to pass the compressed air into the cavity of the fluidized bed in the tank, and the compressed air will fluidize the bulk cement through the canvas of the fluidized bed, so that the fluid bulk cement is Under the effect of pressure difference, it is discharged into the storage bin at the specified height through the discharge pipe. Fluidized bulk cement will flow like a liquid from high to low. In order to continuously flow the fluidized bulk cement in the tank to the discharge port, the fluidized bed inclination angle α and sliding material angle β are introduced into the design of the tank body (see the figure below).

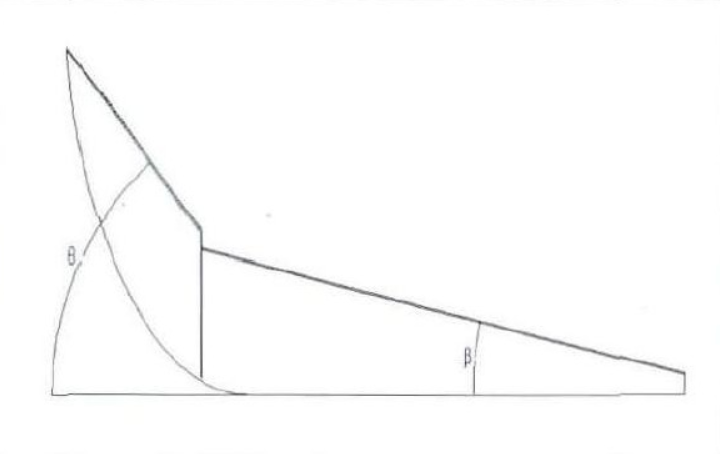

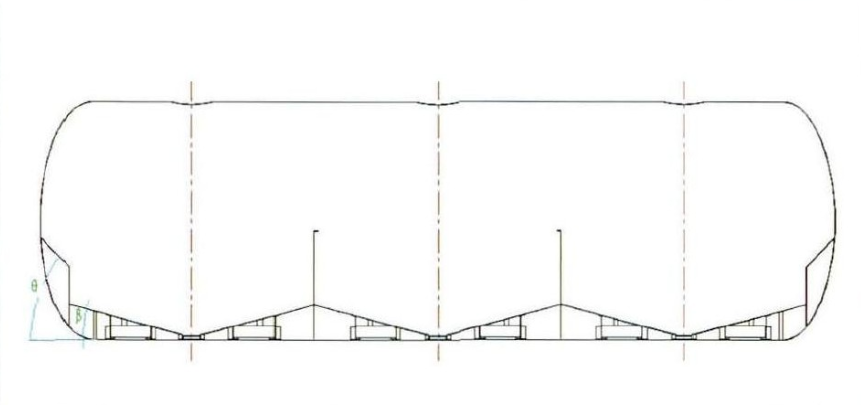

It can be seen from the above figure that the angle formed by the fluidized bed and the horizontal plane is the inclination angle of the fluidized bed β, and the angle formed by the side sliding material plate and the horizontal plane is the sliding material angle θ. When unloading, due to the existence of the inclination angle β of the fluidized bed and the sliding angle θ, the powder material in the tank can flow to the discharge port, and the unloading work is successfully completed. Due to the existence of the fluidized bed and the side sliding material plate, an empty volume is formed under the tank body. In order to reduce the empty volume of the tank and increase the volume utilization rate, the purpose can only be achieved by changing the size of β and 8 under the condition that the internal structure of the tank remains unchanged.

Sectional view of the tank

The internal structure state of the tank body of the bulk cement transport vehicle in the original state is that the angle β formed by the fluidized bed at the bottom and the horizontal plane is 13°, and only the angle θ formed by the sliding plate and the horizontal plane is 47°. The utilization rate of the internal volume of the tank with this structure is not high, only 84%, which directly affects the cargo capacity of the vehicle. Without changing the discharge speed and satisfying the angle of repose of the material (the bulk material can remain naturally stable when stacked) Under the conditions of the maximum angle of the state (the angle of one side to the horizontal plane), called the angle of repose), the improved structural state is that the angle β formed between the bottom fluidized bed and the horizontal plane is 11°, and the side-sliding material plate and the horizontal plane form The included angle θ is 45°. In this way, the volume utilization rate of the entire tank increases by 5%, which greatly increases the load capacity of cement transportation.

The above is the information about the unloading principle of bulk cement trucks. If you are interested in our bulk cement trucks or want to know more about panda bulk cement trucks, you can consult us